When a head gasket blows, it means that this seal has been broken, damaged, or cracked, and will allow compression to escape, improper combustion to occur, or engine fluids to infiltrate parts of the engine through which they were not designed to flow. Slow cooling can be accomplished by wrapping the head in an insulating blanket and keeping the head in a hot box so it will cool at a rate of no more than 200° F per hour. At this rate, it may take 8 to 12 hours to slow cool back down to room temperature. Can You Repair a Cracked Cylinder Head? By Clearwater Cylinder Head. On October 14, 2019. Categories: Cylinder Head Tips. The cylinder head is a vital part of many internal combustion engines. Along with a head gasket and rubber grommets, it seals the cylinders of the engine, ensuring its fuel intake, combustion, cooling and lubrication are all.

Just mentioning the phrase “cracked engine block” sends shivers down the spines of most car owners. Why? Because unlike other engine issues that are simple to repair, like a bad fuse, a cracked radiator hose, or worn brakes. A crack in your engine block is a severe concern that often signals a costly repair (if a fix is even possible at all). If you’ve recently received the news that this might be the diagnosis, you might be asking yourself: “what should I know about a cracked engine block?”

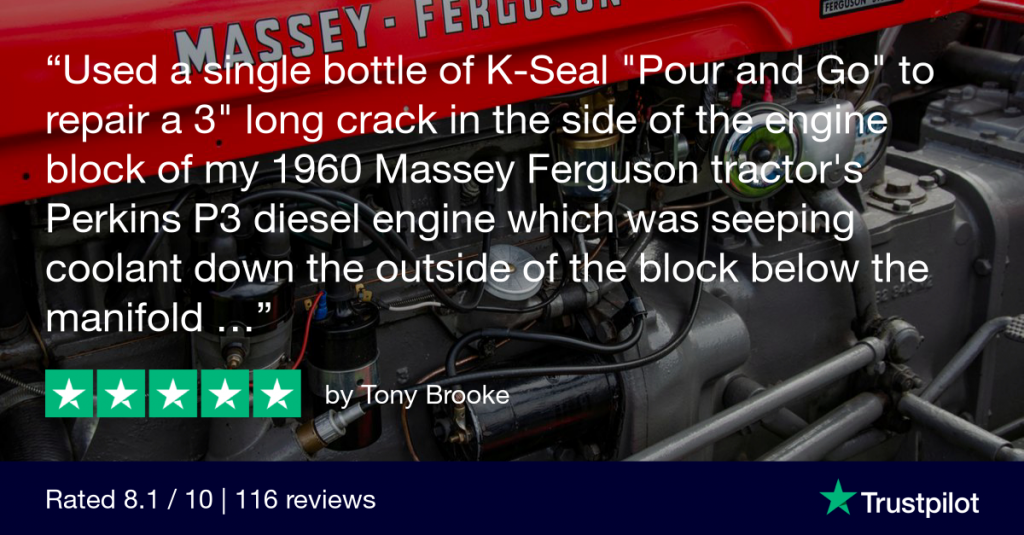

Cracked Head Gasket Fix

Signs of a Cracked Engine Block

- Overheating

One of the first symptoms to watch for is engine overheating. A crack is a perfect place for fluids like coolant and anti-freeze to escape. These two liquids are essential for keeping the engine at an optimal temperature level. When they can’t circulate throughout the block, they can’t do their job. Watch for a temperature gauge in the red, or unexplained low-coolant levels. Know that ignoring an engine that’s running hot will only make matters worse.

- Poor Performance

The pistons rest in the engine block, which is what powers the vehicle. The ignition system delivers a spark from the battery, making an explosion that moves the pistons, creating power. If there’s a crack, then some of that energy escapes, meaning less pressure, which leads to a loss of performance. Watch for a rough idle or low fuel economy, which suggests there’s a crack in the engine block.

- Smoke Emitting from Under the Hood

Blue or gray smoke appearing from under the hood is another indicator of a cracked engine block. The only place you should ever notice smoke coming out is the exhaust pipe. So, if it’s elsewhere, there is a good chance a crack is present. Of course, if this happens, you’ll likely have other symptoms. Such as poor performance, leaks, or overheating.

- Fluids Mixing

One way to tell if there might be a crack in your engine block is to check under the oil cap. Look for milky, white gunk, which signals oil might be mixing with the coolant. These two substances pass through separate sections of the block, so the only way they can mix is if there’s a crack connecting them. If you do see a buildup under the cap, you might also notice a puddle of liquid under your vehicle, which suggests a leak.

- Leakage

Many signs suggest a crack in your engine block, but one of the most obvious is a puddle of fluid under your vehicle. The reason for this is that the areas fluids run through are sealed. But if there’s a crack, they’ll seep through. While a leak doesn’t always imply that there’s a crack present. It does mean you should watch for further signs like overheating or poor performance.

Now that we’ve covered a few of the main symptoms. Let’s review what causes an engine block to crack in the first place.

Causes of a Cracked Engine Block

- Low Coolant

The most common cause of a crack in an engine block (according to most mechanics) stems from excessive heat. Which causes it to expand, creating microscopic fissures that will grow if the issue persists. The purpose of passing coolant through the block is to keep it within a safe temperature range. If you’re running low on engine coolant, then there’s nothing to counteract the heat from rising to dangerous levels. For this reason, be sure to keep an eye on the coolant gauge and add more when it gets low.

- Excessive Stress

You can also cause a crack in your engine block by overworking it. Things like superchargers and turbochargers might boost performance, but they also add a lot of stress on the block. Straight from the factory, engines get built to operate at optimal levels. For this reason, if you do decide to add external parts, be sure to stick with OEM products to mitigate the risks.

Also, be careful you do not overburden your motor when towing a load or trailer. The excess stress might not be the main reason a block can form a crack, but it can contribute. Be sure to consult your owners-manual for the towing specifics of your model.

- Water Pump Failure

Returning to the primary cause of an engine block cracking, overheating. Consider your water pump, which is in charge of circulating coolant through the block to keep it from getting too hot. Signs your water pump is failing include leaking coolant, a whining sound coming from under the hood, or steam coming from your radiator. Most tend to last between 30,000 to 100,000 miles. So, if you’ve never had an issue with yours and it’s in this range, it might be time to get it inspected.

- Manufacturer Defect

While rare, manufacturer defects can result in a cracked engine block. Typically, this stems from a fault made during the molding process that leads to thinning in certain areas. As an example, a recall got issued on 2006 Honda Civics for cracked engine blocks (as well as 07, 08, and some 09 models). If a crack results from a defect, be sure to contact the manufacturer to inquire about possible recalls.

- Extreme Temperatures

Last, but certainly not least – is where in the country you live. As you might have guessed, warmer places increase the risk of overheating. But cold regions pose a danger as well due to freezing coolant. If this happens, it creates pressure against the walls of the block, which can lead to a crack. A great way to defend against this is to ensure you use coolant designed for sub-zero temperatures.

Now that we’ve covered a few of the things that lead to a crack in an engine block. Let’s review the risks of ignoring one.

Risks While Driving with a Cracked Engine Block

- Electrical Shorts

A lot of harm comes from ignoring a cracked engine block. One of these is an electrical short. As you might have guessed, these types of issues are best to avoid due to the difficulty of resolving them. What happens is that when there’s a crack. High-pressure coolant will leak through and soak the surrounding components. Not only do you have to worry about electrical parts under the hood. But there’s also the fuse box to consider, which can affect the entire system.

- Blown Head Gasket

Here’s the main concern you want to avoid, a blown head gasket. Since engine block cracks typically stem from excess heat, it can lead to the heads warping, which is a costly repair. Fixing the block early usually saves you from needing new ones. But if you wait until they blow, the cost goes up substantially. Be sure to keep an eye on the before mentioned symptoms to ensure a cracked engine block repair costs as little as possible.

- Depressurized Cooling System

When your cooling system becomes depressurized, it can cause the coolant to boil. Which lowers how effective it is at doing its job. When it’s not working as it should, it doesn’t cool the entire block properly, which can potentially lead to a blown head gasket.

By now, it should be clear that a cracked engine block can lead to a lot of serious issues. Let’s now look at a few methods to repair one and how much you can expect to pay.

Can You Seal A Cracked Head Gasket

Cracked Engine Block Repair Costs and Methods

There are two types of cracks, internal, and external. The first one is not visible from the outside and typically leads to the mixing of fluids inside the block. The second type is when you’ll notice leakage of oil, coolant, or anti-freeze. Remember that an engine block starts as a single chunk of metal, either aluminum or high-quality iron. Because of this, when you repair it, the area is never as sturdy as it was before the fix. Let’s look at the repair methods:

- Re-welding

Depending on the severity of the crack, you may be able to have it sealed with an arc welder. But, it’s important to note that doing so may lead to deformation of the block. The most substantial factor that contributes to the cost of repairing an engine block is labor, which can get as high as $100 per hour.

- Cold Metal Stitching

There’s also the option to stitch the metal together. Similar to how you’d stitch a tear in fabrics. The issue is that the stitching itself is susceptible to temperature changes, making it not always the best solution. It’s also one of the more costly options to repair a cracked engine block due to it being time-consuming and hard to perform.

- Cold Metal Patches

If you’re after a less costly solution, there are patches available that use epoxies or adhesives to seal the crack. The problem is that they’re not a lasting solution. Similar to stitching, they’re susceptible to high-temperatures. If you choose to go this route, be sure to keep an eye on the before mentioned symptoms that revealed the crack in the first place.

- Commercial Sealers

If you caught a crack in your engine block early, before it gets too large, you might be able to use a commercial sealant. These types of products get added to the cooling system and form a seal between the crack. But, if it’s developed into something bigger, you’ll have to resort to one of the other options to repair a cracked engine block.

And then there are the costs. As we mentioned before, the hourly rate to repair an engine block ran reach as high as $100. Depending on the model of your vehicle, the time required can take as long as 35 hours. If you drive a regular model with a standard engine, such as a Chevrolet Impala with the 3.5-liter V6, you can expect it to take less time. However, if you drive something less-common, like a Chevrolet Avalanche with the Vortec 8100 series, expect it to take longer.

Add in the cost of parts, and you’re looking at an average of about $3,000 to $4,000 to repair a cracked engine block.

Common Questions About a Cracked Engine Block

- Is it Covered Under Warranty?

If your car is still under its manufacturer’s warranty, it’s likely covered, the same goes for extended coverage. If you’re outside your warranty, the best bet is to check if there’s an open recall. However, if the cause stems from an add-on like a supercharger, it might not be valid.

- Can I Sell a Car with a Cracked Engine Block?

Of course, just be sure to protect yourself. It’s always better to disclose any known issues to the buyer rather than hope they never find out. Be sure to include a bill of sale stating the crack got mentioned.

- Is it Worth Fixing a Cracked Engine Block?

It depends on the vehicle. If the cracked engine block repair costs exceed the price of installing a re-built engine instead, then no, it’s not. The same goes for the value of your vehicle, if the fix is higher than what it’s worth, it’s likely time to get rid of it.

Prevention is the Best Way to Avoid a Cracked Engine Block

Finding out you have a crack in your engine block is never a good day. While there are options to repair it, they are rarely worth performing, especially if you drive an older model. Your best bet is to take care of your engine, and always make sure it has enough coolant. If you do notice signs of a crack, get it inspected early, before it gets worse.

If you do decide to get rid of your vehicle, rather than repair it, check out our previous article on selling a broken-down car.

We're back with more on your cylinder head! We recently talked about when you might want to resurface your head, and now we're going to take a look at what you should do if you find that your diesel engine cylinder head has cracks between the valves.

When guys are building their engine, the cylinder head is something that comes up a lot. Read on to find out what to do if you have cracks in your head.

Need some information on a specific head? Our ASE certified techs can help!

There can be Cracks in My Cylinder Head?

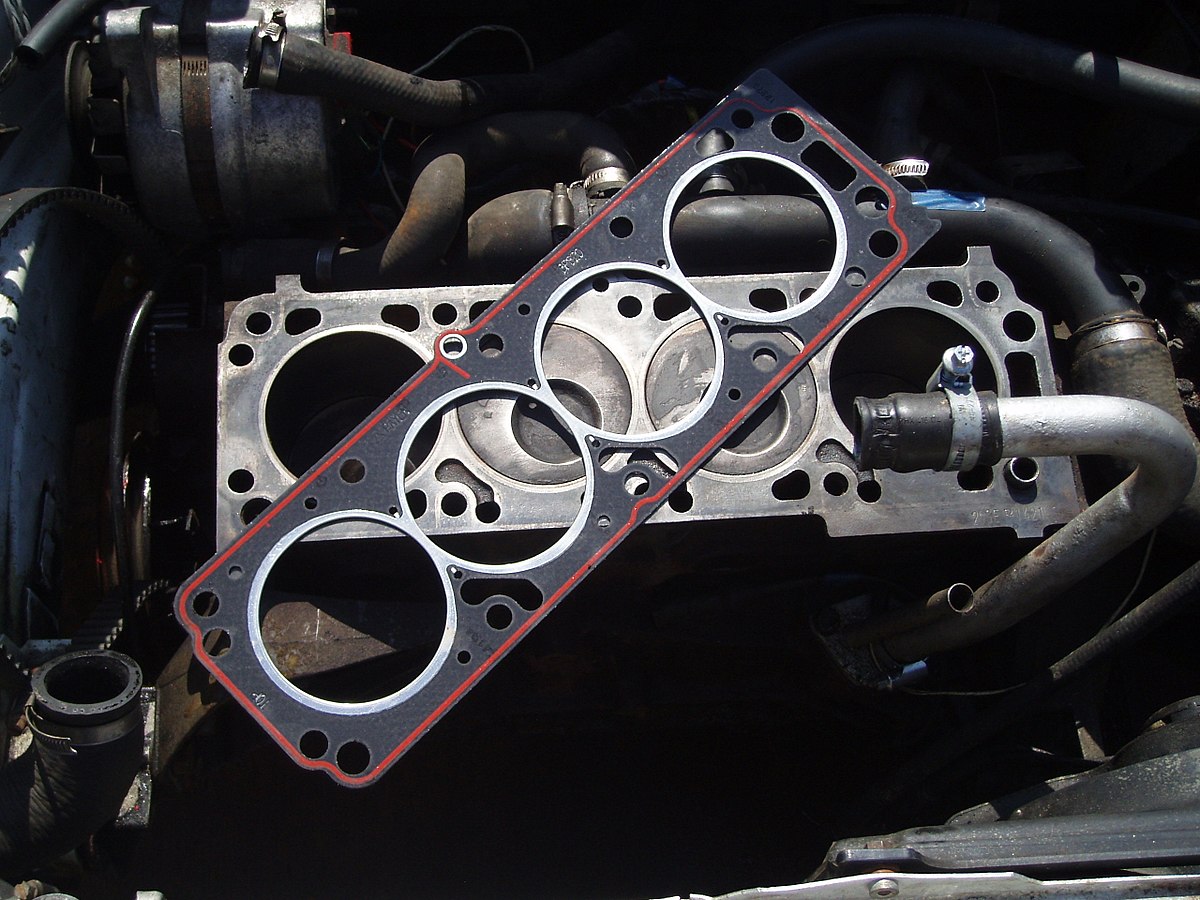

Cracks between the valves is a failure mode that we hear about a lot with cylinder heads. When we talk about cracks, we're looking at the bottom side of your head. You might see some cracks develop in between the valve seats.

Some common causes of cracks in your cylinder head are overheating and stressful operating conditions. Read our failure analysis, Why is My Head Cracked? to learn more about these causes.

These cracks can cause further issues within your engine, including oil contamination, pitting and damage to the engine block, and damage to the cylinders. This could lead to a much larger failure. Cracks in your head are definitely not something you want to ignore. But what can you do?

What do I do About Cracks in my Cylinder Head?

So you have these cracks in your head. This has most guys saying, 'Man, I gotta get a replacement set of heads.'

That's totally understandable. Who wants to put a cracked head back on the engine that you just spent a whole bunch of money on the bottom end?

But one of the things that we need to make sure is that you also fix the problem that causes the cracks in the first place.

When you have a cylinder headtypically a cast iron cylinder headthe metal doesn't just crack on its own. It doesn't just fatigue like that. Usually it cracks for a reason.

Maybe you've got a blown head gasket and it filled the cylinder with combustion gas, which displaced the coolant. This means your cylinder head can't dissipate the heat, so it overheats in that particular area where those air bubbles are forming, and it cracks the head.

Whatever the cause, make sure that you're repairing it before you replace your head, to prevent your new components from failing again.

Can you fix cracks in your cylinder head?

We get it. Replacing a cylinder head costs money. So some guys say, 'Hey, any way I can fix that crack on my cylinder head?'

To that we say yes, cracks are fixable, but it's a much bigger process than you might think. It takes a lot of technology to get it done right.

You don't just want to weld the crack up. That's not always a solid repair. Instead, you want to use a recasting procedure, where the cracks get gouged out and the molten material gets poured back into that crack and recasts that cylinder head. It then gets remachined for a good repair.

It's not something that most guys can do, and it's really time consuming.

That's why we carry complete cylinder heads, whether reman or new, and that's what you're going to need to get your engine back up and going for another reliable million miles. Check out our Signs You Need to Replace Your Cylinder Head, for more reasons you might need a new head.

If you're looking for help installing your diesel engine cylinder head, we have a some helpful install tips!

So when you're replacing your cylinder head, if you've got cracks, make sure you're fixing the overall problem. Check your liner protrusion and make sure you're not going to blow another head gasket. We want you to go another million miles!

Want more help with your cylinder head, or another diesel engine component? We have ASE certified techs on staff to help you out! Give 'em a call at 844-304-7688, or you can request a quote online!